Understanding Bearings Starts with Knowing the Language

In the world of industrial machinery, bearings are small but critical components that keep everything moving smoothly. For maintenance technicians, engineers, and machine operators, understanding the terminology used in bearing specifications and maintenance manuals is essential. This glossary provides a quick yet comprehensive reference to the most important bearing terms you’ll encounter in daily operations and during product selection.

1. Radial Play

Radial Play refers to the total amount of movement between the bearing’s inner and outer rings in the radial direction (perpendicular to the shaft). Too much play can cause vibration and misalignment, while too little can lead to excessive friction and premature wear. Always check the manufacturer’s specifications to ensure proper clearance during installation.

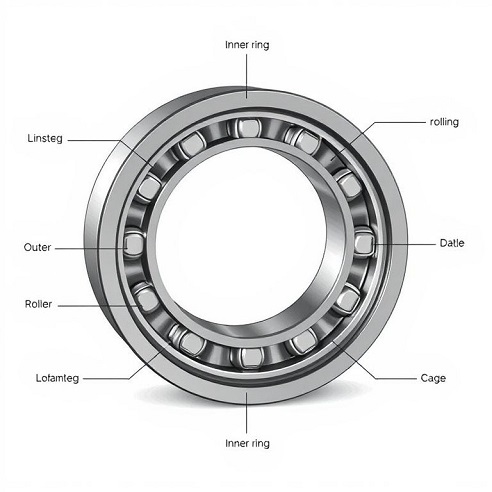

2. Cage

The Cage, also known as a separator or retainer, keeps the rolling elements evenly spaced around the raceway. It prevents contact between rollers or balls, minimizing friction and heat generation. Cages can be made of steel, brass, or high-performance polymers depending on the application and operating conditions.

3. Dynamic Load Rating

The Dynamic Load Rating (Cr) is a key performance indicator that describes the bearing’s ability to handle continuous rotating loads. It represents the load a bearing can endure for a theoretical life of one million revolutions. Higher dynamic load ratings indicate greater bearing durability under motion.

4. Static Load Rating

Unlike its dynamic counterpart, the Static Load Rating (C0r) measures a bearing’s ability to resist deformation when subjected to stationary loads. This value is crucial when bearings are exposed to heavy shock or impact loads while not rotating.

5. Brinelling

Brinelling occurs when excessive load or shock creates small indentations on the bearing raceways. This damage results in vibration, noise, and shortened bearing life. Proper mounting tools, torque control, and shock-absorbing materials help prevent brinelling during installation or operation.

6. Lubrication

Lubrication reduces friction and heat while forming a protective film that prevents metal-to-metal contact. Bearings can use grease or oil lubrication systems, and regular maintenance ensures longer service life and improved reliability.

7. Bearing Clearance

Bearing Clearance defines the total internal space between the rolling elements and raceways. Correct clearance is essential for optimal load distribution and performance. Operating temperature, speed, and load must all be considered when selecting the correct clearance class (e.g., C2, C3, C4).

8. Misalignment

Misalignment happens when the shaft and housing are not perfectly centered. It increases friction and causes uneven stress distribution across the bearing. Using self-aligning bearings or proper shaft-housing fits can significantly reduce misalignment issues.

Why This Matters for Maintenance Technicians

Understanding these fundamental terms improves decision-making in selecting, installing, and maintaining bearings. For companies like DEMY Bearings, precise terminology ensures technicians communicate accurately, leading to reduced downtime and improved equipment reliability.