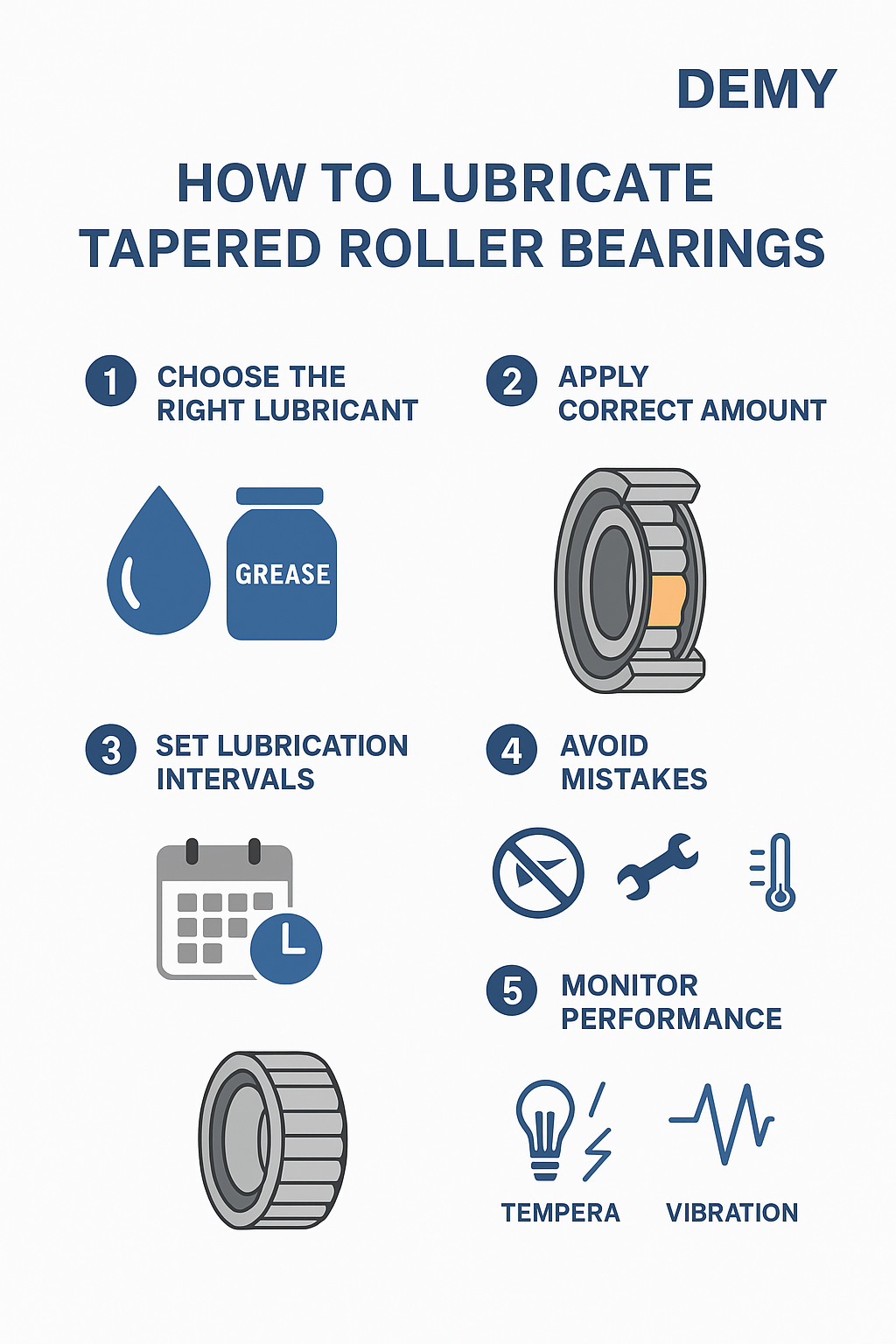

How to Properly Lubricate Your Tapered Roller Bearings to Extend Their Lifespan

Lubrication is the key to ensuring that tapered roller bearings operate smoothly and last as long as possible. These bearings are widely used in automotive, heavy machinery, and industrial applications due to their ability to handle both radial and axial loads. However, without proper lubrication, even the best bearings can fail prematurely. Here’s a practical guide for engineers and maintenance teams on how to lubricate tapered roller bearings correctly.

1. Choosing the Right Lubricant

The first step is selecting the correct lubricant. Most tapered roller bearings perform best with bearing grease that offers a balance of viscosity, thermal stability, and water resistance. In high-speed or high-temperature applications, specialized synthetic greases or oils may be necessary. Choosing the right lubricant reduces friction, prevents overheating, and minimizes wear.

2. Applying the Correct Amount

Over-lubrication is just as harmful as under-lubrication. Too much grease can lead to churning and excess heat, while too little increases friction and wear. The recommended guideline is to fill the bearing cavity to about one-third of its capacity. This ensures smooth rotation and optimal load distribution for your tapered roller bearings.

3. Establishing Lubrication Intervals

Regular lubrication intervals are essential. The frequency depends on operating conditions such as speed, load, and environment. For example, bearings in dusty or wet environments may require more frequent relubrication. Establishing a clear maintenance schedule helps extend the lifespan of the bearing assembly and prevents unexpected downtime.

4. Avoiding Common Mistakes

Some frequent lubrication errors include mixing incompatible greases, using unclean tools, or applying grease at the wrong temperature. These mistakes can lead to contamination, chemical breakdown, or improper distribution of the lubricant. Always ensure that the grease gun, fittings, and storage containers are clean and that only the recommended lubricant type is applied.

5. Monitoring Bearing Performance

Even with correct lubrication practices, regular inspection is crucial. Pay attention to changes in temperature, noise, or vibration. These indicators may signal that the roller bearings are not receiving adequate lubrication or that the lubricant has degraded over time. Proactive monitoring helps identify problems early before they become costly failures.

DEMY Bearing Solutions

At DEMY, we understand that lubrication is one of the most important factors in maximizing bearing life. That’s why our tapered roller bearings are manufactured with precision surfaces and optimized raceway designs that retain lubrication effectively. Whether you need bearings for automotive, industrial, or heavy-duty machinery, DEMY provides solutions that ensure smooth operation and long service life.